CMSD

-0.0100

France is developing domestic production of electric vehicle batteries with an eye on industrial independence but Asian experts are proving key in launching operations.

In the Verkor factory outside the northern city of Dunkirk, which will be inaugurated on Thursday, foreign specialists, notably from South Korea and Malaysia, are training the local staff.

Verkor is the third battery gigafactory to open in northern France in a region that has become known as "Battery Valley".

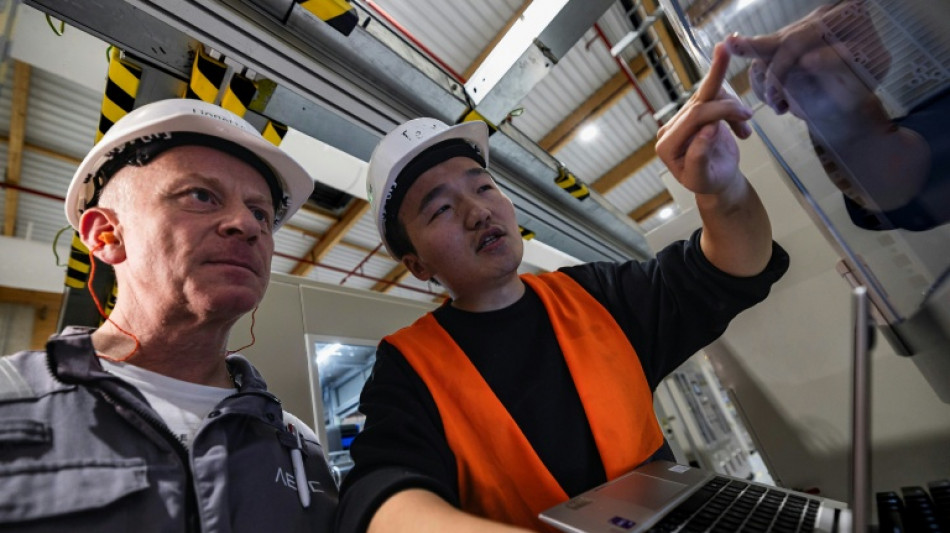

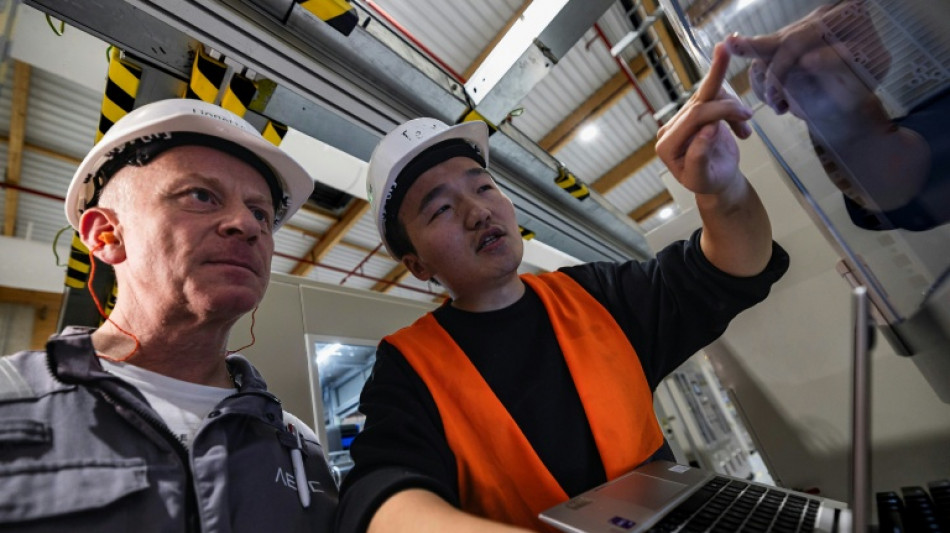

At the AESC factory near the city of Douai, where production has been underway for several months, Chinese engineers and technicians supervise French recruits.

"They are the ones who train us on the equipment, how to operate it, how to fix problems," said Ericka Redjimi, 39.

Redjimi arrived at AESC in May without any experience in the sector.

"I sold clothes at open-air markets," she said.

Communication can prove complicated.

"We use Google Translate often."

"I still need them, much less than at the beginning," but "it's reassuring that they are still here," said Redjimi, who works in the section of the factory that makes battery cells.

Once finished, autonomous robotic sleds transport the cells to another section of the factory where they are assembled into battery modules that are used to power Renault's R4 and R5 models, as well as the Nissan Micra.

- Skills transfer -

By the end to the first quarter of 2026 the factory should be running at full speed, turning out batteries to equip 150,000 to 200,000 vehicles per year, said Ayumi Kurose, who heads up operations at AESC France.

He said the first few months of production had gone pretty much as expected.

"What's always complicated is gaining mastery of the equipment" which often comes from Asia, and the training of staff, Kurose said.

Founded in Japan but now owned by China's Envision, AESC has been manufacturing electric car batteries in Asia for 15 years.

The group can rely on its in-house know-how to ensure "good practices from beginning" at its new factories elsewhere in the world, said Kurose.

He said there are currently nearly 150 Chinese experts working at the Douai directing 800 local staff.

These include experts in vision-based control of industrial machinery and cutting-edge soldering techniques.

"The goal is really the transfer of skills," said Kurose.

The experts "come for between six months and two years, but they aren't meant to stay," he added.

The Douai factory should be ready to operate on its own by the end of 2026, he estimated.

One of the Chinese engineers also expressed confidence.

"I have to say, my French colleagues, they are always working hard," said He Xiaoming, 36.

If they acquire the necessary knowledge and gain additional experience "they will go quite fast", he added.

- Chinese partner -

The nearby ACC factory, the first battery gigafactory to open in France in 2024, is also scaling up production after a difficult start.

"What we manufacture in a day now took us a month to do at the beginning of the year," said ACC's chief executive Yann Vincent.

"We're not yet where we want to be", but in terms of the rate of defective cells and volumes "we've made significant improvement."

A joint venture of carmakers Stellantis and Mercedes-Benz plus energy firm TotalEnergies, ACC earlier this year struck a temporary partnership with a Chinese battery manufacturer.

The company, the name of which ACC hasn't disclosed, will manage one of its three production lines from A to Z until mid-2026.

Vincent said the Chinese have learned an enormous amount in two decades of manufacturing electric vehicle batteries, while France began from zero five years ago.

So "it's better to rely on the people who know best" to speed up learning a "really delicate" manufacturing process.

ACC, which currently employs 1,200 people at its Billy-Berclau factory, aims to manufacture batteries for 250,000 electric vehicles next year, against 10,000 to date.

T.M.Dan--TFWP